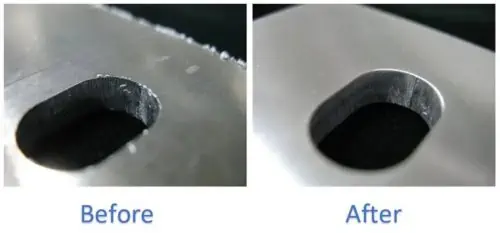

Deburring is a crucial component of the manufacturing process that enhances the product’s final quality by eliminating sharp edges from the surface of a workpiece created by the initial machining processes. Apex Machine Group manufactures custom wet and dry metal finishing equipment that effectively removes unwanted burrs created in the machining process.