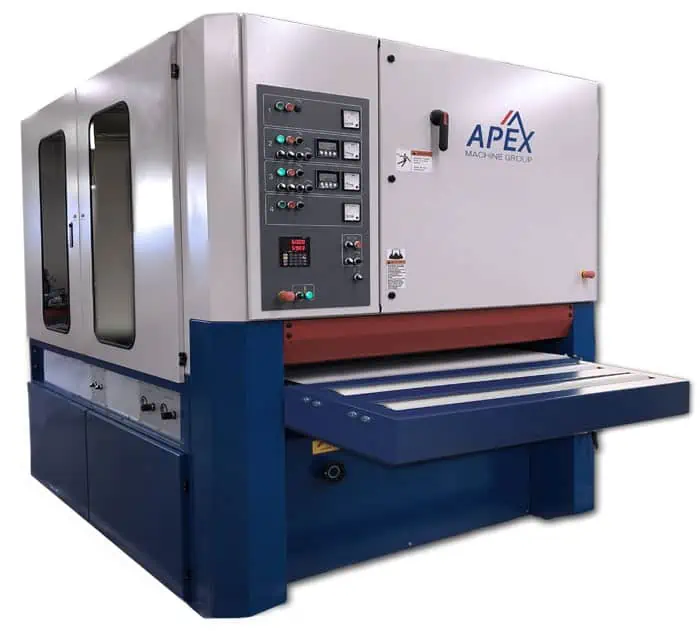

Dry Deburring & Finishing Machines

1000 Series Dry Metal Machines

Built in a heavy duty construction with a smaller footprint designed to accommodate a job shop with various applications such as deburring, dross removal, calibrating/dimensioning, edge radiusing or finishing.

2000 Series Dry Metal Machines

The 2000-Series of machines are built with heavier production requirements in mind. They are designed to handle such applications as deburring, slag grinding, calibrating/dimensioning, edge radiusing, paint/surface preparation, finishing/polishing or a combination of these applications.

3000 Series Dry Metal Machines

These machines are built for the multiple shift and seven-day-per-week operations. Built with the heaviest production requirements in mind to allow you to meet your large production needs whether it be deburring, slag grinding, edge radiusing, paint/surface preparation, finishing/polishing or a combination of these applications.

TopBottom Dry Metal Brush Machines

Top/bottom machine processes both the top and bottom surfaces in a single pass with 100% uniformity. Every square inch of every part is processed exactly the same over 100% of the machine width.

Dry Metal Machines

At Apex Machine Group, we offer top-quality abrasive finishing solutions to meet our customers’ individual application and material requirements. Our machines complete various tasks depending on the application, including deburring, slag grinding, edge rounding, calibrating, and finishing. Among other metal finishing equipment, we offer dry metal machines, which function in many applications and provide numerous benefits.

Our Dry Metal Machines

When selecting a machine to perform metal finishing, deburring, and other processes, you must choose between wet or dry metal machines. These complete the same process using different methods, with wet working machines dispersing a coolant mix onto the surface of processed parts, while dry machines function without this mix.

Our selection of dry metal machines provides solutions for a variety of applications, including graining, deburring, finishing, oxide removal, dimensioning, edge radiusing, and grinding. Depending on the types of materials that require processing, we offer either wet or dry metal machine configurations. We recommend dry machines for grinding processes due to the reduced levels of grit and coarse grit in environments where the temperature isn’t a major factor.

With our machines, you benefit from a longer lifespan, reduced costs, and less frequent maintenance for finishing or deburring.

Why an Apex Machine?

When searching for the right dry metal machine for your application, Apex Machine Group offers some of the most reliable equipment. We provide our customers with a range of dry metal machines to increase the efficiency, dependability, and safety of metalworking applications, such as deburring machines for sheet metal.

Our machines support as many as four working heads, with the ability to customize them with a variety of rotating brushes, abrasive belts, and oscillating disks based on your application’s unique needs.

Whether your application requires compact systems to complete smaller deburring projects or larger, heavy-duty models to complete several shifts and facilitate large-scale production, we’ll help you locate the right machine for nearly any metalworking process.

Industries Served

Our dry metal machines serve industries in woodworking, metalworking, composites, and plastics to allow for more uniform and efficient finishing processes. We distribute our products all over North America to corresponding industries in an effort to help them achieve the best possible finish.

We have clients who rely on our metalworking machines across a range of industries, including the following:

- Pharma

- Food service

- Architectural and elevators

- Automotive

- Aerospace

- Marine

- General manufacturing

- Agriculture

- Job and machine shops

- Structural fabrication

- Medical

Dry Metal Machines and More at Apex Machine Group

Do you need top-quality dry metal machines for your application? You’ll find some of the most reliable designs available at Apex Machine Group. Depending on what you specifically require, we’ll help you find the appropriate solution. In addition to dry metal machines, we offer a selection of wet metal machines, wood machines, EZ sanders, wet dust collectors, and abrasives for a wide range of applications. We build each machine from the ground up based on our customers’ unique needs, regardless of how demanding or specific they are.

For more information about how our dry metal machines can benefit your application, contact us today.