Apex Machine Configuration and Capabilities

Apex Machine Group has been offering high-quality abrasive sanding machines and supplies since 2010. Addressing the needs of both the wood and metal markets, we provide the abrasive finishing equipment needed for processing composite/plastic, wood, and metal products.

Whether you are looking to replace or upgrade an existing piece of machinery, Apex has a full line of machines capable of supporting up to four working heads for optimal results. Our equipment combines oscillating discs, abrasive belts, and rotating brushes to efficiently round edges, remove burr or slag, and polish products in a single pass.

Our equipment automates the hand-finishing process, reducing time-consuming and costly manual labor. High-quality abrasive brushes and abrasive strips help customers achieve optimal sanding results.

If you are looking for precision grinding solutions to move to in-house production, increase your capacity, or expand an existing portfolio, you can trust the quality of Apex machines.

Deburring & Finishing Machine Configuration: Find Your Finish

Our metal finishing technologies meet the different techniques and requirements that customers often request. There are several processes that Apex metal finishing machines can perform, such as:

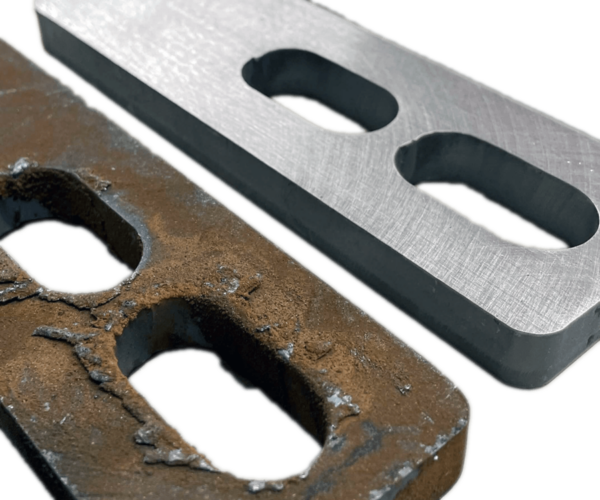

Apex slag grinding machines effectively remove plasma slag, laser dross, and any mill scale left on the part. A hard durometer contact drum equipped with coarse abrasive sanding belts and a high horsepower motor can effectively grind heavy steel plates to remove primary vertical burrs.

Utilizing various grits of abrasives to finish and polish metal creates a refined surface. While a dry process is available, a wet process is better for polishing and finishing metal materials.

Removing the vertical burrs and rough outside and inside edges created from machining operations results in a superior finished product.

To establish an aesthetically uniform grain appearance, a rough section of non-ferrous or ferrous metal receives a fine grain finish using different abrasive grits. The result is near-mirror polishing.

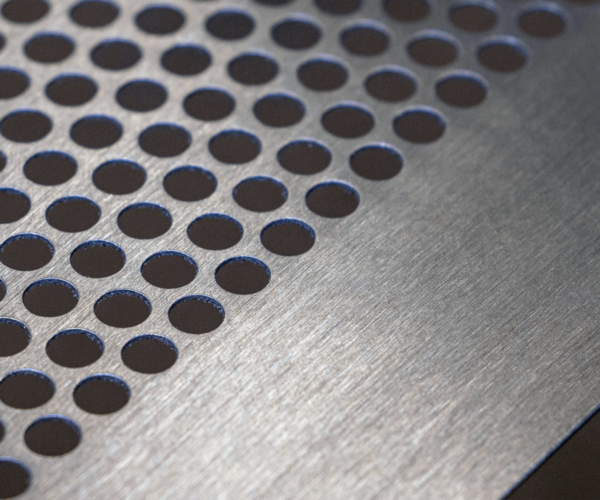

Abrasive finishing removes scallops, nibble marks, and secondary vertical burrs from the edges and holes of processed material to create rounded edges. Oscillating discs with attached abrasive sanding strips break down the deburred parts, achieving an edge radius up to 2mm.

Apex all-in-one versatile machines are significantly safer, faster, and more repeatable than hand deburring operations. One compact design can achieve all of the previously mentioned finishing techniques.

The benefits of using metal finishing technologies from Apex Machine Group include:

- Consistent quality

- Increased worker safety

- Higher operational efficiency

- Improved production quality

- Part consistency

- Time-saving prep for future processes

Our customers can produce finished metal parts with extreme precision without compromising quality. Looking to test out a custom machine configuration? Send us a sample today

Choosing Your Apex Machine Specifications and Options

Apex machines consist of the following:

Selecting Components

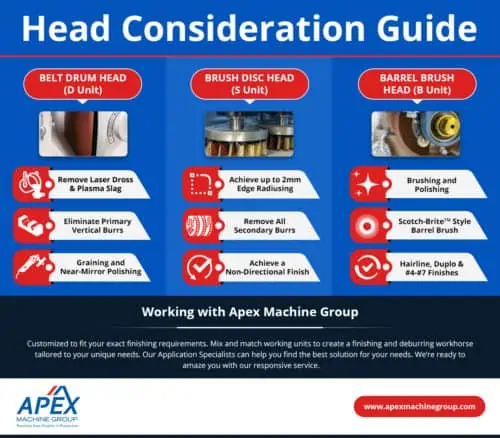

- Brush Heads: Interchangeable heads allow for multiple operations in one pass. Tailor-made mix and match units can meet your unique needs with ease. Available brush head types include:

- Disc brush: Achieves non-directional finish up to 2mm edge radius while removing all secondary burrs.

- Barrel brush: Scotch-Brite™ style, Hairline, Duplo, & #4-#7 finishes.

- Wide belt heads: A variety of wide belt heads are available for larger projects and customized to fit your finishing requirements. Mix and match units are tailored to your specifications and unique needs to provide the perfect finishing and deburring solution.

- Brush Heads: Interchangeable heads allow for multiple operations in one pass. Tailor-made mix and match units can meet your unique needs with ease. Available brush head types include:

Head Configuration Considerations

- Head Combinations: Selecting the right combination of abrasive belt, disc, and brush heads will ensure a properly configured machine for your application. For example, wide belt and barrel brush heads are recommended for grinding, polishing and graining operations, while disc brushes are better suited for deburring, edge rounding and non-directional finishes.

- Number of Working Heads: The number of working heads can impact part integrity and operating temperature. Improper configurations can result in costly defects.

- Number of Passes: Using a single machine with up to four working heads and a wide variety of belt widths allows operations like edge rounding, deburring, grinding, paint preparation, and polishing in one single pass instead of multiple passes, saving time and money.

Other Factors

- Machine Use (single or multiple types of parts): Most configured machines do not have interchangeable parts, making them less flexible for manufacturing lines or shops that utilize numerous components.

- Top vs. Bottom vs. Both: Having brushes on both the top and bottom of the part can allow for more to be accomplished in a single pass saves time and increases overall output. This can, however, increase operating temperatures, which may require a wet machine instead of a dry machine (see “material” below).

- Working Width / Part Width: Apex uses conveyor belts of varying lengths and widths to accommodate parts as small as a business card (3” x 3”), if necessary using our Apex style sticky belt and cleaning device.

- Production Level: We offer three models of multi-function, single-pass machines, including 1000, 2000, and 3000 series. Each one corresponds to production level requirements and the number of shifts per day (0.5 to 3).

- Material: The type of metal or wood being processed will determine if a wet or dry process is required. Other deciding factors include the thickness, grit abrasiveness, and required precision of the material. Additionally, it is essential to determine how many materials will run on the same machine. For example, aluminum is thin and creates combustible dust that can reach high temperatures and distort or reduce a part’s integrity, requiring a wet machine. The two processing methods include:

- WET: We recommend the wet process for finishing thinner parts, such as aluminum, to prevent an increase in temperature and process a higher/finer grit. Utilizing multiple sequential brushes increases the life expectancy of abrasive belts, which are very expensive.

- DRY: We recommend the dry process for grinding processes where a lower, coarser grit is applicable, and temperature is not a primary concern.

- Aesthetic and Precision: Foodservice and pharmaceutical applications require a higher level of precision to avoid contamination. A non-directional finish can effectively eliminate fingerprint smudges. In general manufacturing paint prep applications, precision is less of a concern. Architectural applications value aesthetics, making the industry a good fit for non-directional finishes.

- Cost: Apex understands the importance of finding the correct machine fit to meet the unique needs of our customers. While cost is a deciding factor in choosing the proper equipment, it is not always the best business decision to purchase cheaper machinery for some manufacturing needs.

- Number of Passes and Labor Intensity: Apex machines achieve optimal results in a single pass by utilizing four working heads, along with a combination of oscillating discs, abrasive belts, and rotating brushes. It is possible to remove burr or slag, grind, round edges, and polish the product in one run. This allows for fewer overall passes, saving time and money.

Industries and Applications

Apex Machine Group provides metal finishing technologies for use in a variety of applications for industries that include:

- Pharmaceutical and Food Service: Precision finishing creates a cosmetic finish while lowering the potential for contamination. The finish requires that there are no holes in the material within which bacteria can grow, allowing for a more sanitary finished product.

- Architectural and Elevators: There is an emphasis on form and function, not merely form. The parts must both be aesthetically pleasing and elegant, but also strong enough to withstand daily use and weight-bearing.

- Automotive and Marine: General manufacturing assembly and fabrication are more form-focused, with powder coating and anodizing paint prep considered. Preparation for downstream processing (bending and welding) requires a clean edge free of burrs. How the part fits in the final assembly is affected by the elimination of burrs and potential errors that may negatively impact the tolerance of the final assembly.

- Aerospace: No dust collection is necessary when processing mixed metals and aluminum.

- Other Industries: Agricultural, automotive, job and machine shops, structural fabrication, and many more industries benefit from precision grinding and abrasive solutions.

Configurable Surface Finishing Machines from Apex Machine Group

Replacing or upgrading an existing piece of machinery can be daunting. Our experienced team can help your business eliminate the confusion and transfer from a time-consuming and costly manual process to an automated system.

Apex machines offer the fastest and most economical solutions for grinding, deburring, and edge rounding processes. The equipment is easy to operate with short setup times. Finishing options are flexible with varying degrees of roughness and rounding. Using our equipment adds value to your products by offering a high and constant finish quality.

Apex Machine Group offers a wide variety of abrasive machines that can help you reduce labor requirements and risk of injury while improving consistency and quality of finish. From low-volume runs to large multiple-shift operations, Apex Machines can help simplify day-to-day operations and improve part consistency, helping you outpace the competitors.

Our application specialists have decades of industry experience and can provide affordable, effective solutions, giving you confidence the machine is the right fit for your business.

Contact us today to discuss your business needs. Financing is available, and we can send you a fast, no-obligation sample so you can see for yourself how Apex machines can best meet your application needs.