Apex EZ Sander: The Secret Behind Count’s Kustoms Deburring Success

Introduction Exciting news for the manufacturing community! Apex Machine Group has been featured in The Fabricator magazine alongside Count’s Kustoms. In this article, we will delve deeper into how our Apex EZ Sander has become an integral part of their deburring operations, providing efficiency and precision. This is a must-read for industry professionals looking to…

Machine Configurations For Pre-Processing/Laser Machining

Laser cutting is one of the many technological innovations that have advanced traditional metal processing techniques. This process involves using a high-powered laser beam to cut through or modify the shape of metallic and nonmetallic surfaces. It gained immense popularity in the industry because of its ability to perform precise cuts by heating, melting, and…

Mixed & Rare Metal Part Processing

Click to Expand Metal processing involves changing the shapes, dimensions, properties, and finishes of metal parts before use or assembly. Most metals are easy to machine using basic equipment and techniques, but mixed and rare earth metals have unique chemical properties that require specialized machining processes. At Apex Machine Group, we specialize in various mixed…

The Ultimate Guide to Deburring

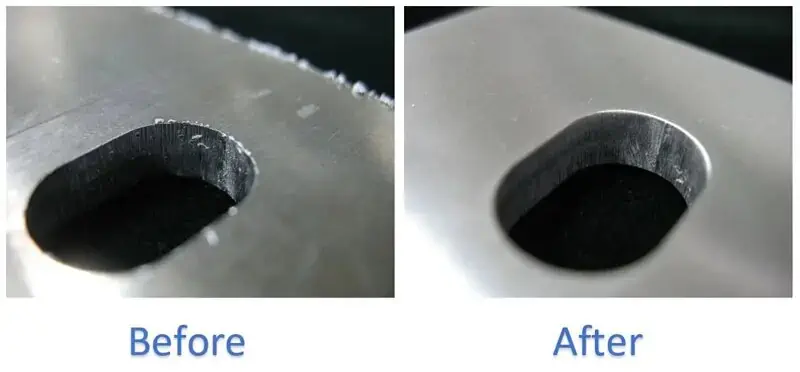

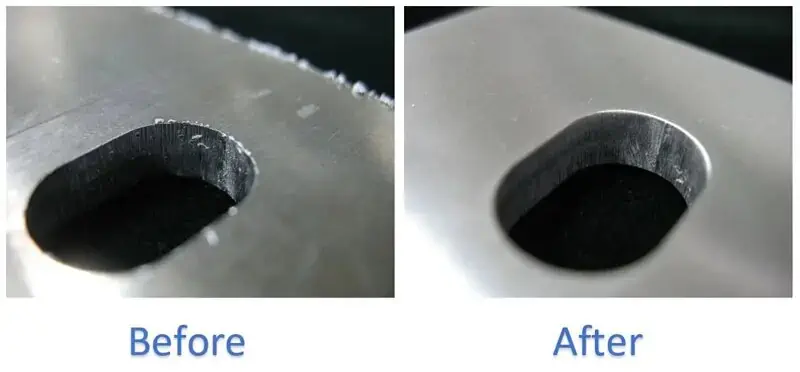

Various machining processes can produce undesired burrs on workpieces of all kinds. Not only are these imperfections unattractive, but they can also negatively affect the performance and safety of the part or component. In these situations, deburring machines can be used to remove burrs and produce smooth, high-quality parts with optimal functionality. Here, we will…

What to Look for When Purchasing a Deburring Machine

Finishing and deburring metal is an essential process for any metalworking shop. With the right deburring machine, your team can quickly remove the burrs and rough edges from formed metal parts, driving more efficient and reliable finishing operations.

How Automating Your Metal Deburring Process Can Increase Productivity

Have you ever considered automating your metal deburring process? If so, you’ve probably looked into a few automated deburring tools for metal—and seen their imposing price tags. Indeed, many companies haven’t incorporated deburring machines into their production yet, largely due to upfront costs. What you may not know is that this investment more than pays for itself by driving shop productivity and performance. At Apex Machine Group , our mission is to make your shop more productive with the finest metal

Metal Edge Rounding 101

Edge rounding (also known as edge radiusing) is the process of removing the vertical burrs, nibble marks, or scallops on the holes and edges of a deburred metal part. Metalworkers use edge rounding to break the edge of processed components, allowing for optimal coating coverage and corrosion protection. As you might expect, there are a variety…

Here’s How to Choose the Right Abrasives for Your Metal Parts

Abrasive tooling is one of the most crucial components of metal finishing. Choose the wrong type, and you’re left with a frustrating deburring process—or a finish that’s not acceptable to your customers. That’s why it’s so important to choose the right abrasives when finishing or deburring metal parts. So then, how should you go about selecting the best abrasive tooling for your shop’s unique needs? At Apex Machine Group, we provide a variety of high-quality metal finishing solutions, including abrasive

4 Common Types of Metal Finishes and How to Achieve Them

Metal finishing is an essential process for producing strong, high-quality metallic products. This is especially true for specialized metal parts that require specific chemical, electrical, or tarnish resistances. There are also many types of metal finishes, which can impact material hardness, workflow speeds, production costs, and more. With so many variables, it can be tough to find the right finishes for your unique metalworking projects, let alone achieve them. So today, let’s review four of the most common (and practical) types

6 Applications of Metal Finishing Equipment

Metal finishing machines are some of the most powerful and versatile solutions on the market. These tools use a combination of abrasive belts, rotating brushes, oscillating discs, and customizable heads to process metal parts in a single pass—and fully automate your metalworking processes. Wet and dry metal finishing machines are also compatible with many types of materials, making them ideal across a wide variety of applications. Let’s explore some of the core applications of metal finishing equipment to give you

Repairing a Metal Finishing Machine vs. Buying New Equipment

Even the best metal finishing solutions break down over time and constant use, especially if your shop runs multiple shift, seven-day-per-week operations. Unfortunately, a busted machine can cause significant downtime and grind your production process to a screeching halt. To avoid that loss in productivity and keep your work running smoothly, you’ll need to service or replace your malfunctioning equipment, stat. Repair or replace—which approach will work best for your unique needs? As a global leader in the metal deburring and finishing

Should I Purchase A Deburring Machine?

Deburring is an essential step across metalworking operations. This process efficiently removes the rough edges and burrs from metal materials that are created from various machining operations, including drilling, punching, and shearing. Traditionally, deburring is completed by hand using specialized tool sets. Unfortunately, these tools are drastically less efficient and productive compared to dry metal finishing machines. If you’re thinking about upgrading your shop’s deburring process with a dedicated machine, it’s important to understand the benefits and potential drawbacks of

Wet vs. Dry Metal Finishing Equipment

Metalworking machines are designed for a wide variety of applications, ranging from removing slag and burrs to polishing metal products. Metal finishing (or polishing) is particularly essential when producing metal components or parts. This finishing process makes metal surfaces more resistant to corrosion, rust, and typical wear—significantly improving the quality and lifespan of metal products. As a world leader in the metal deburring and finishing market, Apex Machine Group takes pride in delivering the most efficient and powerful metal finishing

Automating Your Metal Deburring Process

Whether your shop is machine cutting with a laser, flame, or plasma table, the process of manually deburring flat metal parts is very similar. The cutting machine operator unloads cut parts, places another sheet onto the table, and activates the machine. While the machine is cutting the new sheet, the table operator manually grinds any burrs or slag off the edges of newly cut parts. As the operator finishes grinding parts, the cutting table has completed its next operation. The

Intro to Metal Finishing

Many terms are used to describe metal finishing: straight graining, grinding, finishing, straight-lining, brushing, timesaving, #4 finish, dairy finish, sanding, polishing, and I could keep going. It does not matter what you call it, the beauty is in the eye of the beholder (i.e. your customer). These expectations can vary from aesthetics to engineering callouts and quality control tolerances, or a combination of the two. Whether you are just starting your research, a growing company looking to bring this process

5 Ways to Improve Your Deburring Process

It does not matter if you are cutting your parts with a state-of-the-art laser or hand-holding a plasma torch, cut quality and consistency will affect down-stream processes. A perfectly square edge from your fiber laser sounds good in theory, but what will you do when your assembly workers start getting cut from the sharp edges? Let’s say your largest customer just added a deburring/edge quality requirement on all of their prints. Do you have enough capacity to accommodate this request?