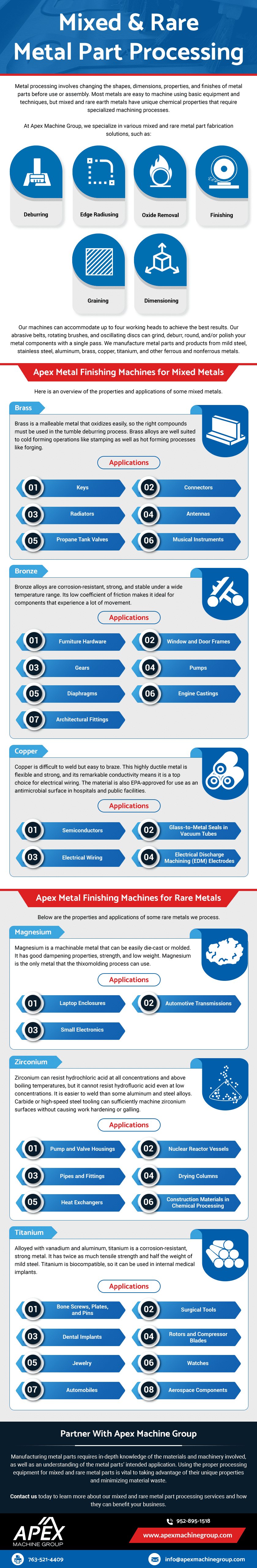

Metal processing involves changing the shapes, dimensions, properties, and finishes of metal parts before use or assembly. Most metals are easy to machine using basic equipment and techniques, but mixed and rare earth metals have unique chemical properties that require specialized machining processes.

At Apex Machine Group, we specialize in various mixed and rare metal part fabrication solutions, such as:

- Deburring

- Edge radiusing

- Oxide removal

- Finishing

- Graining

- Dimensioning

Our machines can accommodate up to four working heads to achieve the best results. Our abrasive belts, rotating brushes, and oscillating discs can grind, deburr, round, and/or polish your metal components with a single pass. We manufacture metal parts and products from mild steel, stainless steel, aluminum, brass, copper, titanium, and other ferrous and nonferrous metals.

Apex Metal Finishing Machines for Mixed Metals

Also known as alloys, mixed metals combine two or more metals to create a new metal, which usually has enhanced properties from the individual metals.

Here is an overview of the properties and applications of some mixed metals.

Brass

Brass is a malleable metal that oxidizes easily, so the right compounds must be used in the tumble deburring process. Brass alloys are well suited to cold forming operations like stamping as well as hot forming processes like forging.

Applications

- Keys

- Connectors

- Radiators

- Antennas

- Propane tank valves

- Musical instruments

Bronze

Bronze alloys are corrosion-resistant, strong, and stable under a wide temperature range. Its low coefficient of friction makes it ideal for components that experience a lot of movement.

Applications

- Furniture hardware

- Window and door frames

- Gears

- Pumps

- Diaphragms

- Engine castings

- Architectural fittings

Copper

Copper is difficult to weld but easy to braze. This highly ductile metal is flexible and strong, and its remarkable conductivity means it is a top choice for electrical wiring. The material is also EPA-approved for use as an antimicrobial surface in hospitals and public facilities.

Applications

- Semiconductors

- Glass-to-metal seals in vacuum tubes

- Electrical wiring

- Electrical discharge machining (EDM) electrodes

Apex Metal Finishing Machines for Rare Metals

Rare earth metals are a group of 17 elements found in the Earth’s crust. They are not rare in terms of total amount but rather they tend not to be concentrated in large enough amounts at single locations to justify the economic cost of mining them. However, the unique properties of rare earth metals mean they cannot be substituted with other metals.

Some rare earth metals are flammable and need to be cooled when processed. Our wet deburring machines use a liquid coolant during processing that prevents metal chips from heating and sparking inside the machine.

Below are the properties and applications of some rare metals we process.

Magnesium

Magnesium is a machinable metal that can be easily die-cast or molded. It has good dampening properties, strength, and low weight. Magnesium is the only metal that the thixomolding process can use.

Applications

- Laptop enclosures

- Automotive transmissions

- Small electronics

Zirconium

Zirconium can resist hydrochloric acid at all concentrations and above boiling temperatures, but it cannot resist hydrofluoric acid even at low concentrations. It is easier to weld than some aluminum and steel alloys. Carbide or high-speed steel tooling can sufficiently machine zirconium surfaces without causing work hardening or galling.

Applications

- Pump and valve housings

- Nuclear reactor vessels

- Pipes and fittings

- Drying columns

- Heat exchangers

- Construction materials in chemical processing

Titanium

Alloyed with vanadium and aluminum, titanium is a corrosion-resistant, strong metal. It has twice as much tensile strength and half the weight of mild steel. Titanium is biocompatible, so it can be used in internal medical implants.

Applications

- Bone screws, plates, and pins

- Surgical tools

- Dental implants

- Rotors and compressor blades

- Jewelry

- Watches

- Automobiles

- Aerospace components

Partner With Apex Machine Group

Manufacturing metal parts requires in-depth knowledge of the materials and machinery involved, as well as an understanding of the metal parts’ intended application. Using the proper processing equipment for mixed and rare metal parts is vital to taking advantage of their unique properties and minimizing material waste.

Contact us today to learn more about our mixed and rare metal part processing services and how they can benefit your business.