Apex Machine Group provides top-quality abrasives and replacement products for your industrial needs. Whether you’re looking for belts or strip brushes, we offer a wide selection of options that can help you achieve the perfect level of material removal and the right finish in any application.

Apex Machine Group’s Abrasive Belt/Strip Brushes

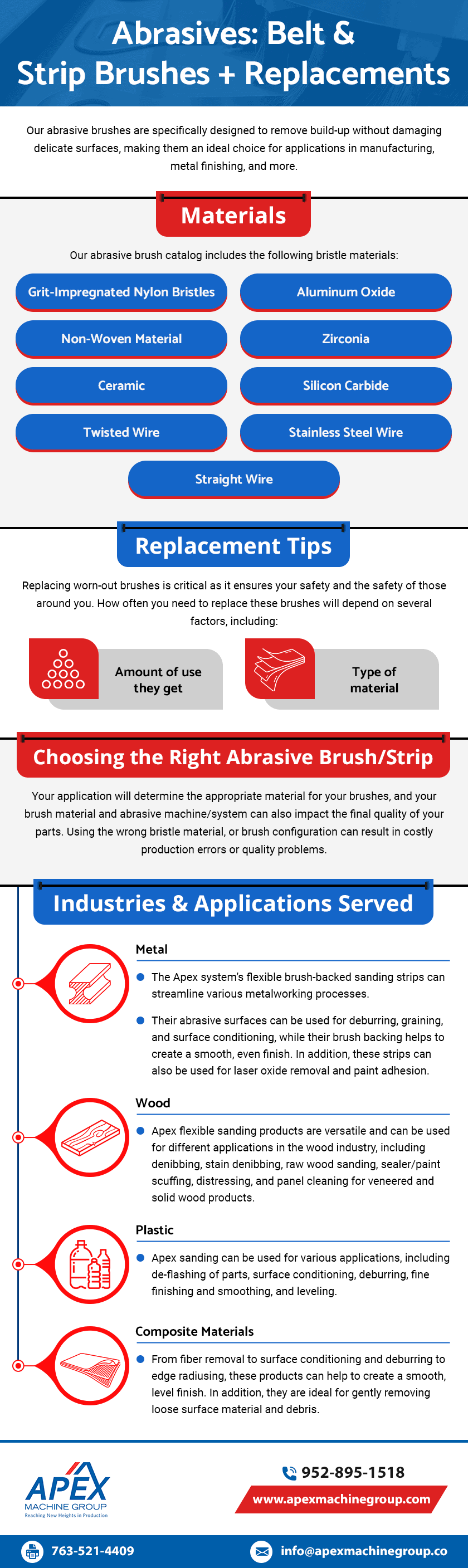

Our abrasives belts feature a standard tension design that delivers optimal performance with no downtime, helping you get the job done right and on time. Our abrasive brushes are specifically designed to remove build-up without damaging delicate surfaces, making them an ideal choice for applications in manufacturing, metal finishing, and more.

Materials

Belt/strip brushes can be made from various materials and come in a variety of sizes and shapes to suit different needs. For example, some belt/strip brushes have tapered bristles to reach tight spaces, while others have stiff bristles for more aggressive cleaning.

Our abrasive brush catalog includes the following bristle materials:

- Grit-impregnated nylon bristles

- Aluminum oxide

- Non-woven material

- Zirconia

- Ceramic

- Silicon carbide

- Twisted wire

- Stainless steel wire

- Straight wire

With so many options available, Apex Machine will have the right brush for any job.

Replacement Tips

Belt/strip brushes should be replaced regularly to optimize their performance and keep them in good working condition. How often you need to replace these brushes will depend on several factors, including the amount of use they get and the type of material they are made from. For example, brushes used for heavy-duty cleaning may need to be replaced more often than those used for light cleaning. Replacing worn-out brushes is critical as it ensures your safety and the safety of those around you.

Choosing the Right Abrasive Brush/Strip

Your application will determine the appropriate material for your brushes, and your brush material and abrasive machine/system can also impact the final quality of your parts. Using the wrong bristle material, or brush configuration can result in costly production errors or quality problems. Wet vs. dry abrasive machines can also impact the safety of your manufacturing facility, as well as the costs associated with production.

For assistance choosing the right brush or system for your needs, contact us today.

Industries & Applications Served

Apex Machine Group makes high-quality sanding systems for various materials, including wood, plastic, composite, and metal, in different industries like aerospace, agriculture, food service, manufacturing, and construction.

Metal

The Apex system’s flexible brush-backed sanding strips can streamline various metalworking processes. Their abrasive surfaces can be used for deburring, graining, and surface conditioning, while their brush backing helps to create a smooth, even finish. In addition, these strips can also be used for laser oxide removal and paint adhesion.

Wood

Apex flexible sanding products are versatile and can be used for different applications in the wood industry, including denibbing, stain denibbing, raw wood sanding, sealer/paint scuffing, distressing, and panel cleaning for veneered and solid wood products.

Plastic

Apex sanding products are essential tools for the plastics industry. These products can be used for various applications, including de-flashing of parts, surface conditioning, deburring, fine finishing and smoothing, and leveling.

Composite Materials

Apex flexible sanding products offer a versatile solution for various needs in the composites industry. From fiber removal to surface conditioning and deburring to edge radiusing, these products can help to create a smooth, level finish. In addition, they are ideal for gently removing loose surface material and debris.

Whatever the application, Apex Machine Group’s abrasive strips are up to the task.

Abrasive Finishing Machines and Parts from Apex Machine Group

Abrasive machines are a critical part of any industrial setting. When choosing the right machine and replacement parts, it’s important to choose a supplier you can trust. Apex Machine Group can help you find the finish you need with our top-quality abrasives and replacement products. Contact us today to learn more about how we can help you get the job done right.