Top and Bottom Deburring Machine

Deburring, Edge Radius, Laser Oxide Removal, Surface Prep

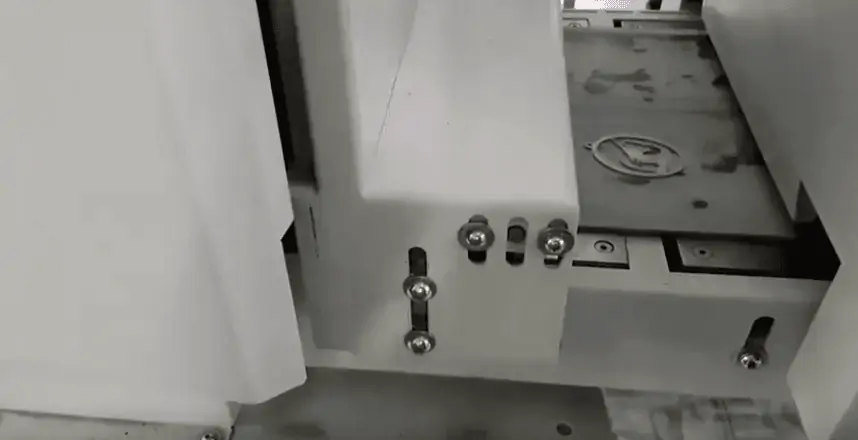

The Apex TB-1600 Top/Bottom machine processes both the top and bottom surfaces of parts in a single pass with 100% uniformity. Every square inch of every part is processed exactly the same over 100% of the machine width. It is equipped with oscillating and rotating sanding discs designed for effective deburring, edge radius, laser oxide removal, weld-point clean-up and surface preparation for powder coating, painting and e-coating. The machine has two single row disc stations on top, with each top disc station consisting of twelve 150 mm (6″) discs. There are two single row disc stations on the bottom, with each bottom disc station consisting of twelve 150 mm (6″) discs for processing the bottom of parts.

MACHINE FEATURES

- Machines built in widths from 40″ to 100″, depending on maximum width of parts to be processed

- Separate variable speed adjustment for disc rpm and oscillation

- Convenient pull-out of disc station on left and right for speedy changing of abrasive sanding strips

- Rotation of discs is reversible

- Features constant pass-line (900 mm)

- Pressure rollers for holding parts down

- LED lights mounted inside the machine for clear visibility

- Dual infeed and outfeed support pinch rollers to ensure parts feed through machine properly

- Heavy duty chain-driven feed rollers

MACHINE SPECIFICATIONS

Thickness of

Workpiece

Motor for Disc Station Rotation 2.2kW

Motor for Disc Station Oscillation 0.37kW

Number of Discs

Diameter of

Sanding Discs

Feed Speed

Dust Collection

Ports

Dust Collection Requirements

Machine Weight

Machine Dimensions

Minimum 0mm to Maximum 80mm

100-700 rpm

40 rpm, oscillation movement 100mm

12 discs x 2 rows (top) and 12 discs x 2 rows (bottom)

150 mm (6″); 250 mm (10″) available

3-25 feet per minute

Three (3) 150mm ports per disc station

Minimum 6,500 CFM

6,050 lbs.

84″ L x 90″ W x 80″ H

MACHINE VIDEOS

TB-1600 64″ Wide Top/Bottom Brush Machine

Deburring, edge radius, and surface scuffing on an Apex TB-1600