Abrasive Finishing Solutions

Apex Machine Group manufactures a range of wood and metal processing machines that allow for faster, safer, cost-effective and consistent operations. We provide all-in-one solutions, customizing each unit to your requirements. Our machines can perform multiple tasks to reduce production time and costs. When you partner with us, we will consider factors like part size, production level and material type to configure a tailored solution. Our application specialists select the right interchangeable heads to enable the following tasks:

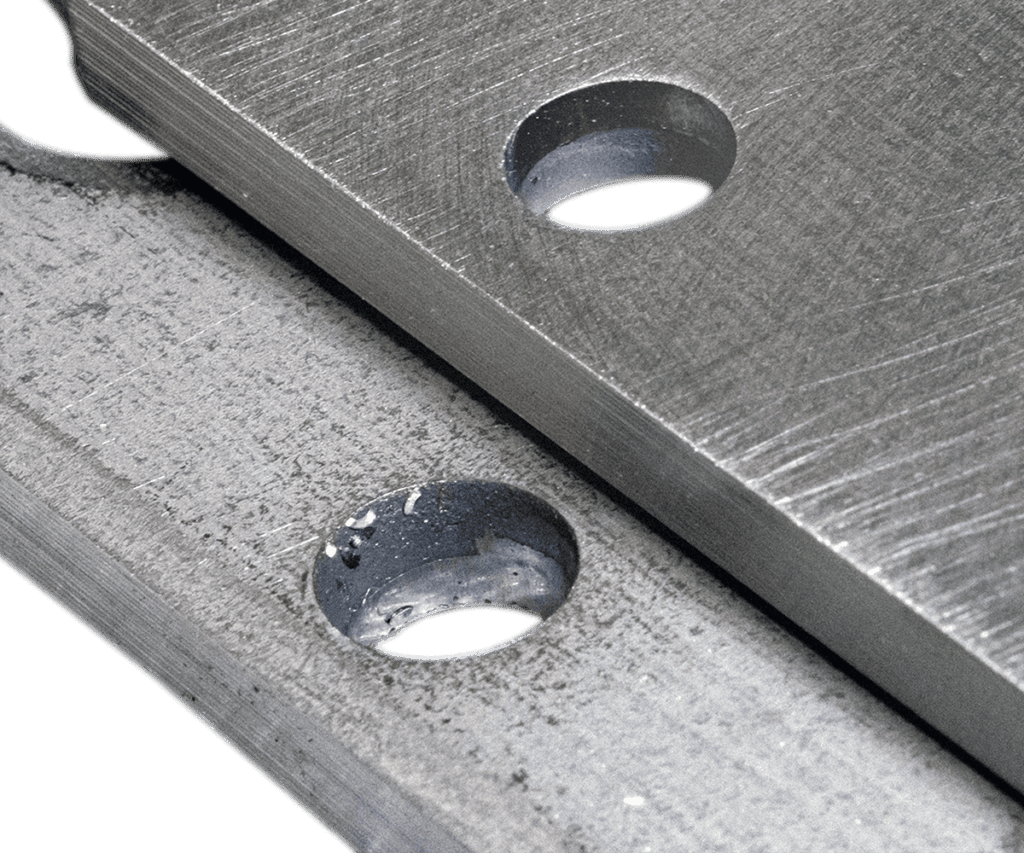

Deburring

Deburring is a crucial step in the manufacturing process. It ensures quality and consistency by removing edges or burrs left on metal parts. Our CNC deburring solutions increase the efficiency, accuracy and consistency of metal deburring.

Apex machinery can process a wide range of parts, from complex shapes with hard-to-reach areas to large surface areas. They feature various working heads, belts, and rotating brushes to remove rollover, poisson and breakout burrs.

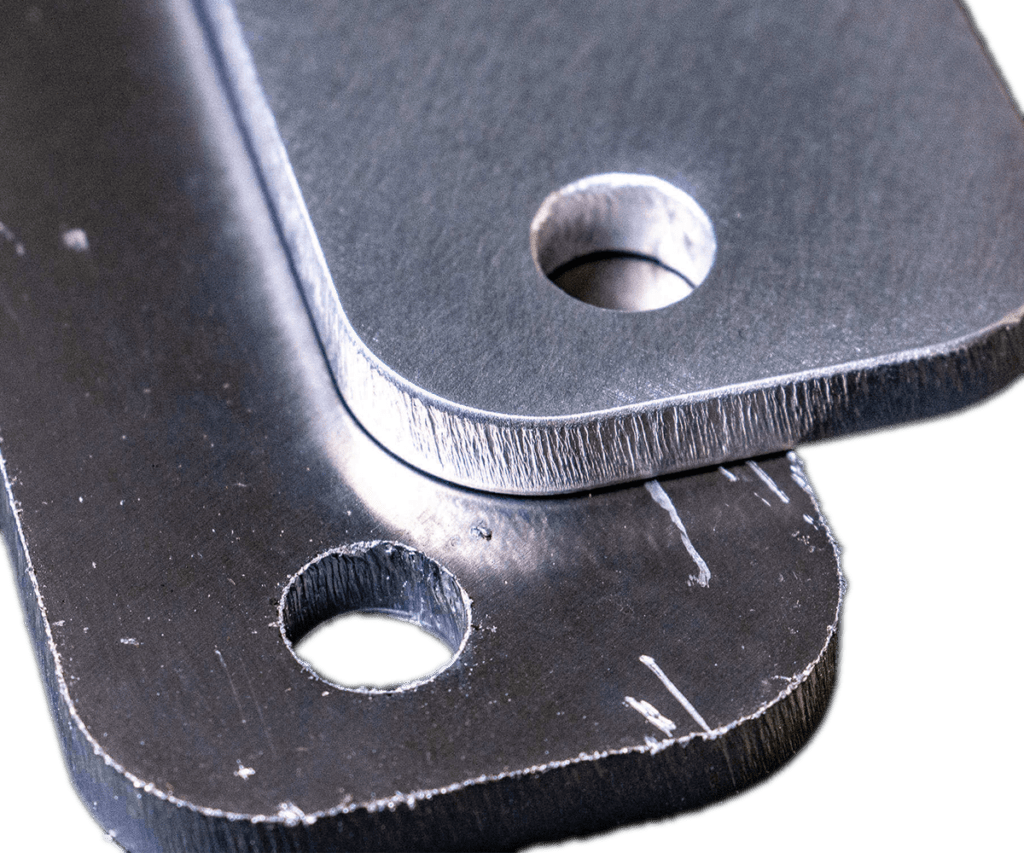

Edge Rounding

Edge rounding achieves a safe and uniform finish for metal parts. Our customizable units can be equipped with oscillating discs with sanding strips that achieve uniform rounded edges on a part’s perimeter or around holes. They offer superior precision and control with a consistent radius of up to 2 millimeters, even for parts with complex geometries.

Automating this process reduces the risk of injury with minimal manual intervention. Precise edge rounding also improves the quality and durability of parts, reducing the risk of abrasion, breakage or failure.

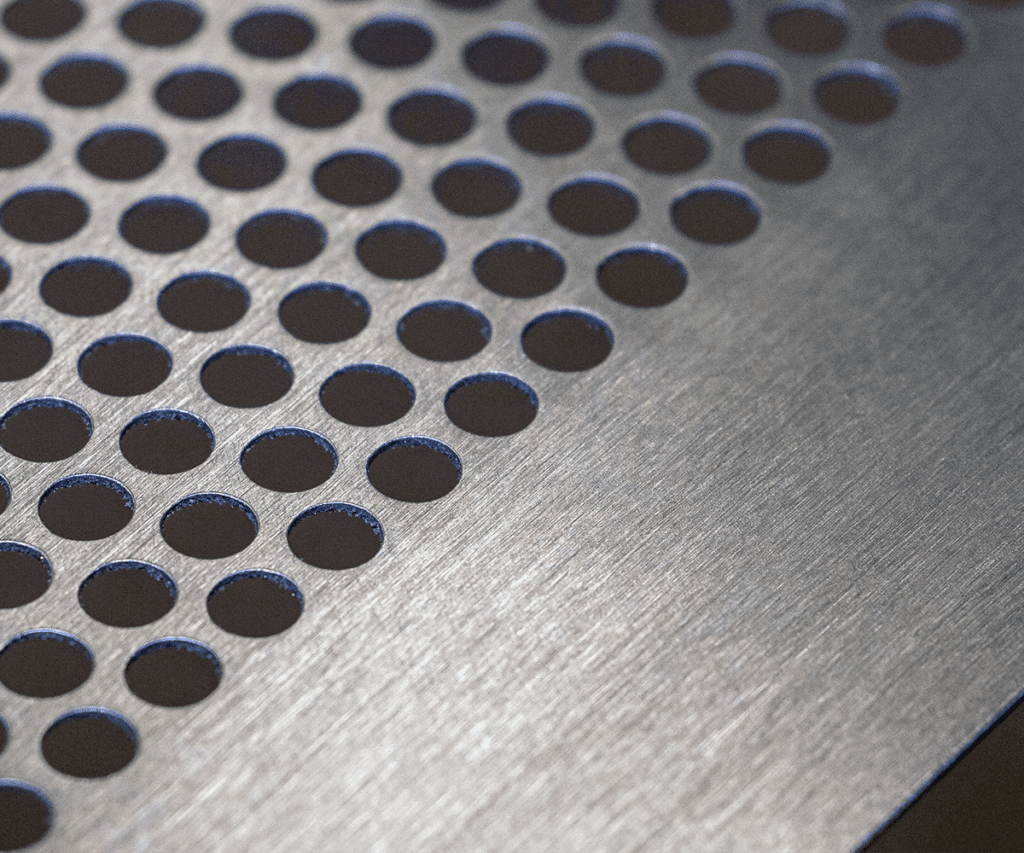

Surface Finishing and Polishing

Polishing and finishing improve metal parts, enhancing their strength and appearance. Our surface finishing solutions have wet and dry configurations to refine, modify or shape a substrate. We can equip them to perform various finishing procedures, from wet polishing to achieve a reflective surface to graining for nonferrous metal components.

Our abrasive finishing machines can also feature veneer platens, brush sanders and other equipment for sanding wood, plastic and composites. These custom units can feature up to four combination heads and varying grits to achieve the surface quality you need.

Grinding and Slag Removal

Slag grinding removes any excess metal from processed parts like heavy slag and dross. This process is crucial to maintain compliance with health and safety regulations. Apex Machine Group offers complete grinding and slag removal solutions to ensure compliance with minimal risk of failure and downtime.

Our slag grinders remove all types and amounts of slag accumulation. Our top-quality equipment ensures optimal efficiency, reducing the risk of failure and protecting surrounding equipment and output from slag.

Paint and Surface Preparation

Surface preparation is a crucial step to ensure an effective and long-lasting coating. Metal graining removes surface defects from parts to create a smooth, uniform finish and allow for proper coating adherence. Our superior grinding and brush sanding machines create the ideal surface for painting, powder coating or anodizing in a single pass.

We have decades of experience in the surface preparation process. Our machines clear any residue and create the perfect scratch for mechanical bond — they can also be configured to achieve primer-coat scuffing.

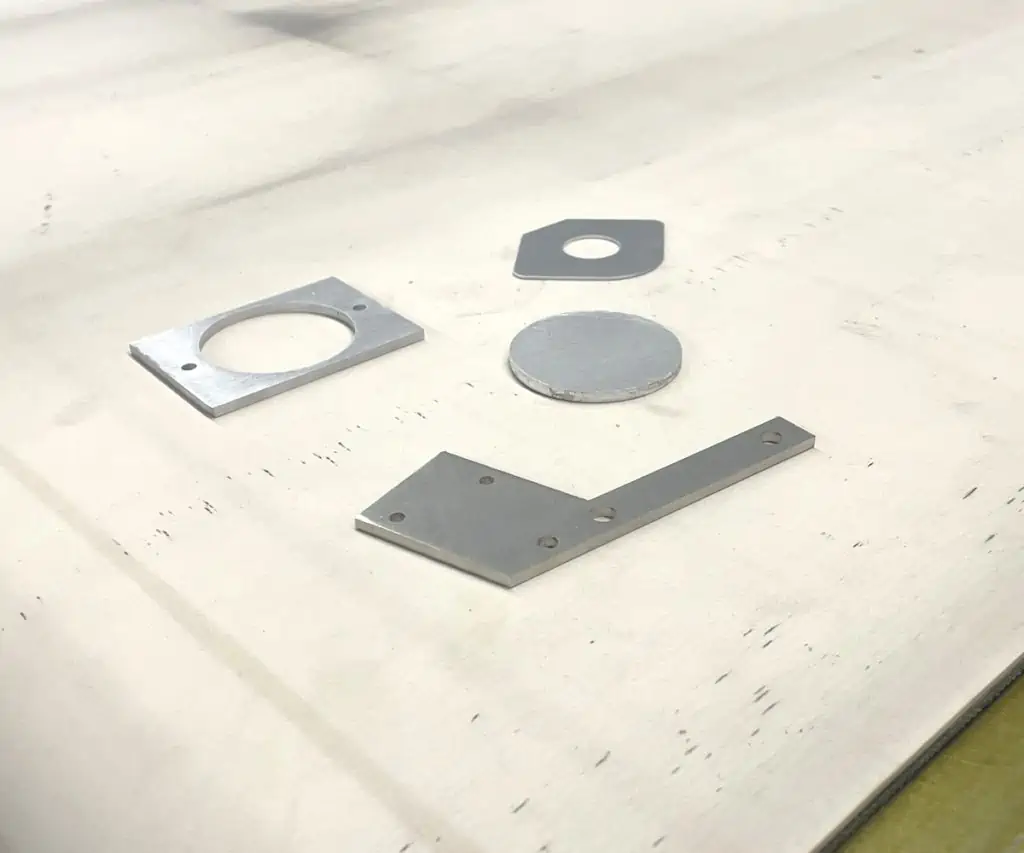

Processing Small Parts

Apex Machine Group offers reliable and cost-effective CNC solutions for processing small or micro parts. Our innovative conveyor machines can process parts as small as one square inch with high levels of precision.

Wood Solutions

Wood finishing adds a protective layer to workpieces and improves the appearance of a wooden surface. Apex Machine Group offers high-quality finishing solutions for softwoods, plywood, hardwoods and engineered materials. Our machines have multiple capabilities, including sanding, calibrating, brushing, finish sanding and distressing.

Get a Solution for Every Application

Apex Machine Group is your trusted partner for complete finishing optimization. Contact our team online or call us at 952-895-1518 for a customized solution tailored to your processing needs.