The Importance of Deburring

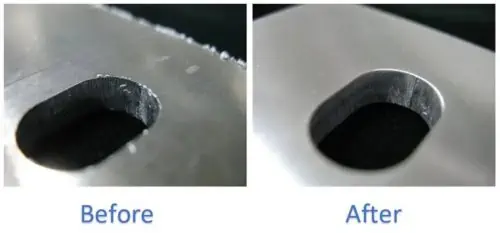

Deburring is an essential finishing process to ensure a high-quality end component with maximal working life potential. The benefits of deburring are evident and include the following:

- Safer material handling and increased safety

- Higher quality products

- Increased efficiency

- Saves money

- Flexibility

- User friendly

Why Automate Your Deburring Process?

Automated deburring machines offer manufacturing facilities a significant edge over manual methods. CNC deburring machines for sheet metal are equipped to handle higher volumes of parts while maintaining precision and speed. This allows for faster production cycles, higher quality and consistency, which results in an increase in productivity and profitability.

Deburring is considered a potentially hazardous task. Using CNC machines will allow you to reduce the risk of injuries with reduced manual intervention and relocate skilled workers to more critical processes.

The Apex Machine Group Solution: Single-Pass Deburring Configured for Your Parts

Apex Machine Group is your trusted deburring machine manufacturer. We provide businesses across different industries with efficient and precise sheet metal deburring equipment tailored to their applications.

When you partner with us, our team will analyze your processing needs and provide a custom solution, whether you work with high-volume batches, small parts or large metal sheets. Our all-in-one machines can be equipped to perform multiple processes in a single pass, saving more time and resources while providing quality results.

Our Deburring Technology

We provide a wide range of precision deburring solutions. Our units support up to four interchangeable heads, allowing the combination of oscillating discs, rotating brushes and abrasive belts for optimal deburring. They can be configured to meet your part size, production level, material type and required aesthetics.

Our efficient deburring lineup can process a wide range of materials. We can configure our machines to remove challenging burrs from stainless steel, treat lightweight aluminum sheets or process small flat copper parts.