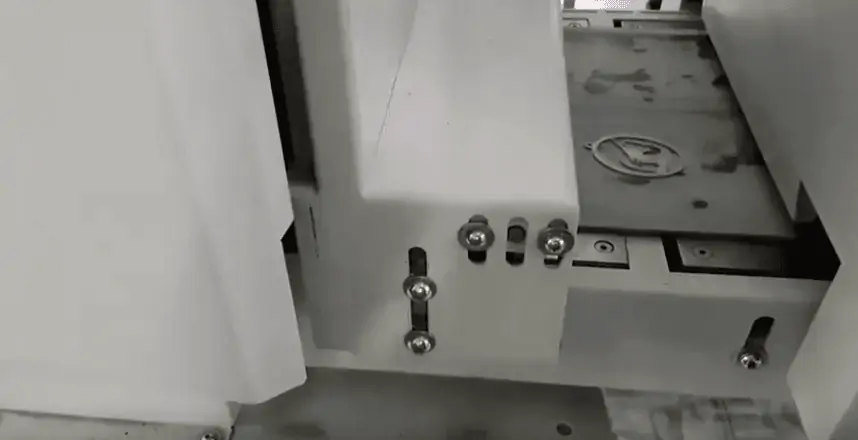

1000 Series Dry Metal Finishing Machine

Deburring, Grinding, Edge Radiusing

The 1000-series of machines are built in a heavy duty construction with a smaller footprint designed to accommodate a job shop with various applications such as deburring, dross removal, calibrating/dimensioning, edge radiusing or finishing. This series of machine can be built in both top and bottom configurations.

MACHINE FEATURES

- Machines built in widths from 13″ to 43″ and multiple head frames

- Dual infeed and outfeed pinch rolls to ensure parts feed through machine properly

- One- to three-head configurations with drum, brush, disc or combination drum/brush/disc heads

- Machines built in both top and bottom configurations

- Individual cam adjustment down to .001″ per head for accurate finishing

- Air-loaded cylinder for automated belt tensioning

- Automatic abrasive belt tracking to ensure proper belt alignment during operation

MACHINE SPECIFICATIONS

SPECIFICATIONBelt Width

Motor Size

Number of Heads

Types of Heads

Available

Drum Size

Machine

Configuration

Feed Motor

DESCRIPTION13″ to 43″

5 HP to 30 HP

1 to 3

Drum, Scotch-Brite, Brush and Disc

100 mm to 200 mm

Top-Only, Bottom-Only, or Top/Bottom Configuration

1 HP to 3 HP

MACHINE VIDEOS

1037M-DSc With Sticky Belt and Conveyor System

Rust Removal, Deburring, and Edge Radius in a Single Pass of a Carbon Steel Part Using an Apex 37″ Belt/Disc Machine