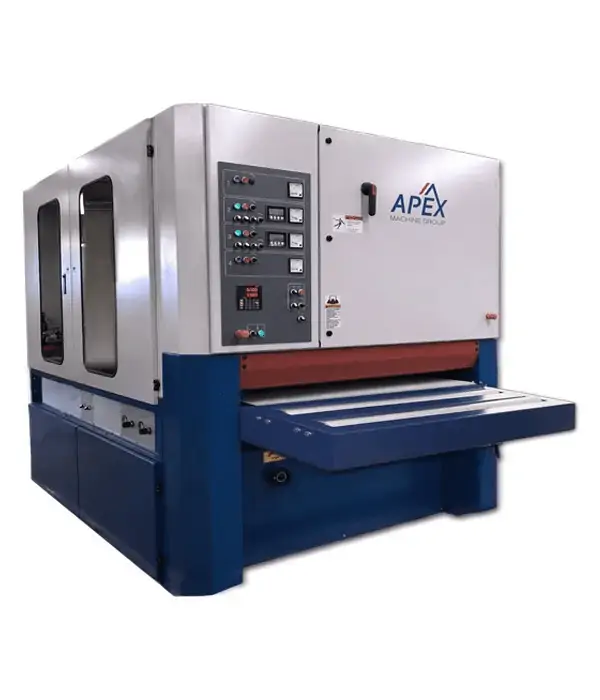

3000 Series Dry Metal Finishing Machine

Deburring, Grinding, Edge Radiusing

Built with the heaviest production requirements in mind to allow you to meet your large production needs whether it be deburring, slag grinding, edge radiusing, paint/surface preparation, finishing/polishing or a combination of these applications. These machines are built for the multiple shift and seven-day-per-week operations. This series of machine can be built in a top and bottom configurations.

MACHINE FEATURES

- Heavy-duty construction allows for 24-hour per day operation

- Machines built in widths from 25″ to 64″ and multiple head frames

- Dual infeed and outfeed pinch rolls to ensure parts feed through machine properly

- One- to three-head configurations with drum, brush, disc or combination drum/brush/disc heads

- Machines built in both top and bottom configurations

- Individual cam adjustment down to .001″ per head for accurate finishing

- Air-loaded cylinder for automated belt tensioning

- Automatic abrasive belt tracking to ensure proper belt alignment during operation

MACHINE SPECIFICATIONS

SPECIFICATIONBelt Width

Motor Size

Number of Heads

Types of Heads

Available

Drum Size

Machine

Configuration

Feed Motor

DESCRIPTION25″ to 64″

15 HP to 75 HP

1 to 4

Drum, Scotch-Brite, Brush and Disc

150 mm to 360 mm

Top-Only, Bottom-Only, or Top/Bottom Combination

3 HP to 7.5 HP