The EZ Sander is the cost-effective solution for shops that need reliable, high-quality finishing without the complexity of oversized systems. Designed for deburring, edge rounding and finishing applications, this versatile metal sander machine helps you achieve consistent results across a wide range of parts.

Whether you’re looking to reduce labor costs, speed up production or improve safety with cleaner edges, the EZ Sander delivers the performance of a large machine in a compact, affordable package.

Finish Parts From Any Application

The EZ Sander for metal is engineered to handle parts from virtually any cutting process, including plasma-cut plates and laser-cut components. Its heavy-duty construction and flexible controls allow you to process parts from:

- Plasma and laser cutting: Clean dross and sharp edges quickly for a uniform finish.

- Waterjet cutting: Smooth abrasive edges without altering material integrity.

- Stamping and punching: Remove nibble marks and burrs for safer, ready-to-coat surfaces.

Key Finishing Capabilities

The EZ Sander addresses the following challenges with engineered precision, giving you an all-in-one solution for finishing:

- Burrs that cut hands

- Sharp edges that cause assembly issues

- Heavy slag that slows throughput

- Inconsistent surface quality that leads to rework

Small Deburring and Edge Rounding

The EZ Sander functions as an efficient small deburring machine, removing burrs quickly and applying a clean, rounded edge. This improves part safety and helps ensure better coating adhesion.

Superior Surface Finishing and Polishing

With the right abrasive belt, the machine creates everything from a smooth, paint-ready surface to a polished finish with a consistent grain. The result is a professional look and enhanced performance.

Slag Grinding and Removal

Heavy slag can be difficult to remove manually from plasma-cut parts. The EZ Sander’s wide belt sander for metal has a powerful grinding capability to efficiently remove these parts, saving time while protecting the base material.

EZ SANDER MACHINE FEATURES

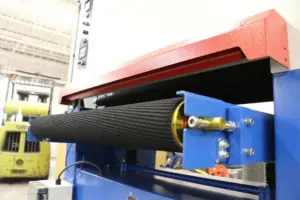

- 36″ wide part capacity

- 37″ x 60″ abrasive belts

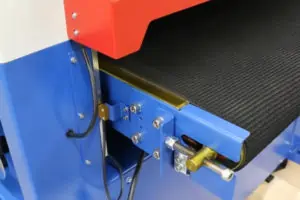

- Variable speed conveyor at 5-25 fpm

- 5″ bed opening with motorized lift

- Digital thickness readout for conveyor height

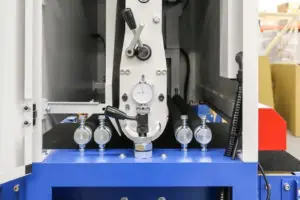

- Control panel with motor load meter, hour meter, and digital readout

- Electronic abrasive belt tracking

- Pneumatic abrasive tensioning

- Air operated disc brake

- 6″ diameter cam adjustable contact drum with dial indicator

- Heavy-duty welded frame

- Casters for portability

- Optional portable 5 HP wet dust collector

EZ SANDER MACHINE SPECIFICATIONS

PART PROCESSING LIMITATIONS

* Minimum part length is approximate and can vary by application or optional features. Please contact us to discuss your specific application needs.

Metal EZ Sander Shown with Optional Portable Wet Dust Collector (Model PWDC-5)