Installing, maintaining and replacing the abrasives in your deburring equipment ensures you avoid facing preventable downtime and inefficiencies.

At Apex Machine Group, we offer the highest quality abrasives, including strip brush replacement products. From strip brushes to belts, our extensive selection of abrasives allows you to attain flawless material removal and application finish goals.

Contact a specialist to discuss which abrasives would tailor fit your needs.

Abrasive Strip Selection Guide: Finding the Perfect Strip for Your Deburring Machine

Two important considerations should guide your choice of abrasives — the application and the materials.

Contact an Abrasives Specialist

Application-Specific Solutions

The brush material or abrasive system you require will be determined by its application, including whether or not your deburring environment is wet or dry. If you use the wrong type of bristle or brush configuration for your system, you run the risk of poor quality output and lower productivity.

Abrasive Materials

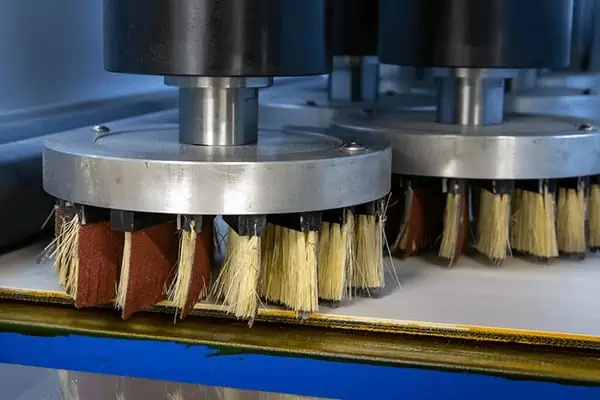

Abrasives such as strip brushes come in various materials, shapes and sizes. Choosing the correct material enables you to get a consistent result.

Some of the more popular types of strip brush bristle materials available through Apex Machine Group include aluminum oxide, ceramic, zirconia, twisted wire, stainless steel wire, straight wire, grit-impregnated nylon, non-woven material and more.

Abrasive Strips to Fit Your Deburring Equipment Technical Specs

Every deburring machine requires abrasive strips and sanding brushes that match from a technical spec perspective. If you are new to purchasing abrasives, our specialists can walk you through your choices based on your deburring equipment.

Strip brushes and abrasives come in different sizes and materials. As noted above, the materials used to make strip brush bristles matter. Tougher brushes tend to be more appropriate for heavy-duty applications, whereas sanding brushes made from less abrasive materials are more suitable for delicate jobs.

The life cycle of abrasives also varies. The wear-down rate of an abrasive can depend on many factors, including how much the brushes are used and the materials they abrade. Plus, some abrasives are designed to wear down differently depending on their shape. Our specialists can help you understand the performance expectations of any abrasive model that you find in our catalog.

Industry-Specific Applications

An advantage of working with Apex Machine Group is our deep experience working with customers from many industries, including aerospace, agriculture, food service, construction and manufacturing. Although all customers have unique applications, three of the more common include:

- Metal processing applications: Flexible brush-backed abrasive sanding strips are often the right fit for the deburring, graining, laser oxide removal and surface conditioning of metal parts to achieve a smoother, more even finish.

- Woodworking applications: Woodworkers can use abrasives on veneered and solid wood to denib, sand, scuff, distress and clean without damaging the product.

- Plastic and composite applications: For plastics and composites, abrasive strips and brushes can uniformly deflash, surface condition, debur, fine finish, smooth, level and round. Additionally, strips and brushes can loosen unwanted surface debris.

Custom Abrasive Strip Installation and Industrial Sanding Brush Replacement Solutions

At Apex Machine Group, we understand the importance of having all the right parts for your deburring equipment, down to the abrasives. Trust our expertise for delivering high-quality, tailored abrasives that help minimize downtime and improve efficiency. Call us at 952-895-1518 today!