Many terms are used to describe metal finishing: straight graining, grinding, finishing, straight-lining, brushing, timesaving, #4 finish, dairy finish, sanding, polishing, and I could keep going. It does not matter what you call it, the beauty is in the eye of the beholder (i.e. your customer). These expectations can vary from aesthetics to engineering callouts and quality control tolerances, or a combination of the two.

Whether you are just starting your research, a growing company looking to bring this process in house, or improve your current operation; it can always be helpful to step back and get back to the basics to be sure you are looking at the whole picture.

Customer Expectations

The goal of any process is to meet the needs of any downstream “customers”. These can be internal customers (painting, assembly, marketing/sales, quality control, etc.), or external customers (the people paying for this operation). Either way, “The customer is always right” …Right? Understanding a customer’s finish requirements and expectations is the most important step in this whole process, if not the most challenging.

Two customers may specify that they need a “#4 finish”. One of those customers may only be asking for a basic grain finish, while the other customer is really asking for a “#4, pit-free, sub-32 Ra, dairy-finish”. Are you over-delivering on the basic request (or even pricing yourself out of the market because your internal #4 finish is the more expensive dairy-finish)? If this is a new customer, is the first batch of parts going to be rejected because your terminology did not match expectations?

Finish Specifications

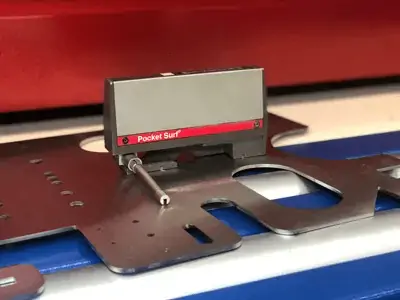

When discussing a finish with your customer, it is important to understand both the technical and aesthetic requirements. A technical requirement is usually in the form of a surface roughness measurement, with the most common unit of measure being Ra (Roughness average) in either micro-inch (μin) or micro-meter (μm) – Ex. Ra of 10-15 μin. A special tool called a profilometer uses a small stylus to measure the surface profile (distance between the top and bottom of the scratch), with starting prices around $2,000. Before running out to buy the lowest cost profilometer you can, keep in mind that more specialized units of measure may be specified by your customer (RMS, Rv, Rp, Rt, Rz, Etc.), so plan accordingly.

A roughness specification only addresses the surface profile of the part, and not the visual aspect of the scratch pattern. You can achieve a 100 μin Ra with an angle grinder, orbital sander, widebelt sander, or dragging the parts through the parking lot. Each one of those options may technically meet the requirement, but will they be accepted by the customer?

A requirement that can be both technical and aesthetic is grain pattern and direction. If a customer needs a 35 μin Ra “no way” finish, you will either need to use an orbital sander or non-linear brush. This is sometimes called out due to down-stream processes (like bending or painting).

Aesthetic requirements can be some of the most challenging finishes to consistently provide. This is usually the case when a company purchases pre-finished material (or outsources the finishing work) and wants to “touch up” any scratches or defects in-house. It is next to impossible to match a coil-to-coil mill finish with a feed-through sander; both machines use the same technology (wide belt abrasives and brushes) but machine parameters and operating conditions will never be the same.

Beauty is in the eye of the beholder, and acceptable finishes may be a moving target when meeting a visual quality requirement. It is advantageous to maintain swatches/samples of parts that have been accepted by your customer for future reference and troubleshooting. Sometimes minute changes to machine operation (e.g. new brand of abrasive, new coolant, machine wear and tear) can have drastic results to the look of a part – resulting in rejected parts.

Operating conditions may look identical on paper, so the cause and effect of something as simple as a different abrasive supplier can be hard to pinpoint.

Grinding Metal

With all of that talk about small changes making big differences, and beauty is in the eye of the beholder, how do I make sure I’m not setting myself up for some major headaches? Well, the parts being processed (material, geometry, quantity) and the required finish are the deciding factors in what machine/process you need to use. If the parts are already assembled or this is an infrequent request, using different hand tools may be all you need. (3M offers a variety of solutions for this very need: https://www.3m.com/3M/en_US/metalworking-us/applications/finishing/.)

A popular option for applying a long scratch to sheet metal is a stroke sander, where a very long and narrow abrasive belt is rotating above your stationary part. The operator then uses a handle to push the abrasive down to sand the part. This allows for sanding fabricated parts that may deflect (like a door or cabinet), but is slow and results are directly tied to operator performance.

For the majority of flat parts, the best option for a metal finishing machine is a feed-through wide belt sander. The process control (quality) is more repeatable, operator fatigue and safety are improved, throughput increases, and your cost per part is controlled. Many standard machine configurations and options are available, so buying a machine configured to your needs doesn’t need to come with a “custom” price tag.

Automated Metal Sander

Now you are saying to yourself, “You know, a widebelt sander seems to be what I need. I saw a good deal on one being auctioned from cabinet company…Where’s my credit card?” … STOP! Just because it looks like water, doesn’t mean you should drink it. Not all wide belt sanders can run metal, let alone give you a good finish. Machines that were configured for woodworking should not be used for metalworking for a variety of reasons (including safety, dust hood location, abrasive direction + speed, types of rubber, etc.).

If you want to buy the right machine for your situation, then you need to talk over your needs with someone who has extensive application knowledge (such as the team at Apex Machine Group: https:/contact/request-for-quote/).

Reviewing your finishing requirements will allow a machine builder to present you with a few machine options and can discuss the pros and cons of each so you can make an informed decision. This conversation will likely lead to the machine builder running your parts on their machine. The machine builder can then adjust and document specific machine parameters and abrasives, which will be used in building/configuring your new machine. This also provides the value of you approving the machine’s finish and will have a great starting point to dial in your new process as you run production.

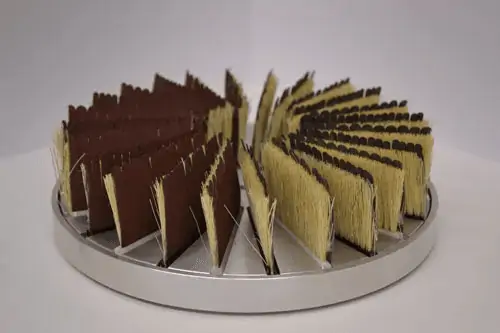

Abrasives

Any piece of equipment can only be as good as its tooling allows. Notice I did not mention anything about price there. As with anything, an optimal combination exists between machine + tooling/abrasives + application. You can think of it like tires on a car: cheap/expensive, aggressive/smooth, performance/mileage, racing/all-terrain/snow. It does not matter how expensive the car is or how much power it has; if you don’t have the right tires, the car won’t perform as advertised.

It is possible to get good enough performance out of a budget product, but it might come at a cost (short life, poor consistency, etc.) because the supplier buys whatever bulk abrasive is cheapest when they need it. By using an abrasive company that glues the rocks onto the paper themselves, you will get consistent performance and repeatable finishes.

Upgrade Your Finish Today

Now is the perfect time to invest in an automated solution to make your finishing operations faster, more consistent, and efficient. Apex Machine Group is proud to offer a wide range of automated finishing and deburring equipment, so visit apexmachinegroup.com to see who we are and what we do. If you’d rather skip through all the keyboard research and reading, give us a call at 1-855-500-2739 or send us an email at info@apexmachinegroup.com.

We look forward to hearing from you!