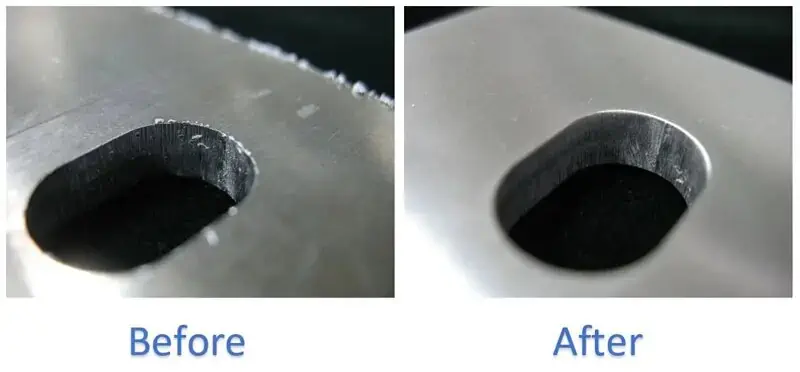

Various machining processes can produce undesired burrs on workpieces of all kinds. Not only are these imperfections unattractive, but they can also negatively affect the performance and safety of the part or component. In these situations, deburring machines can be used to remove burrs and produce smooth, high-quality parts with optimal functionality. Here, we will discuss deburring, how it works, when it’s used, and how Apex Machine Group can help with your deburring needs.

What is Deburring?

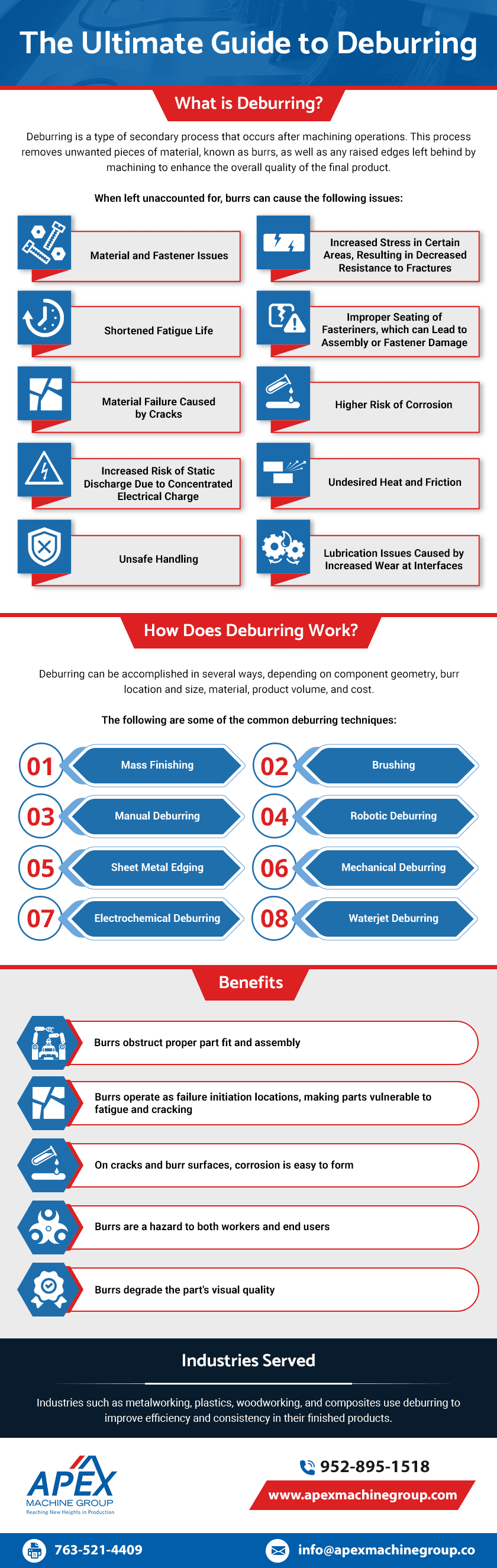

Deburring is a type of secondary process that occurs after machining operations. This process removes unwanted pieces of material, known as burrs, as well as any raised edges left behind by machining to enhance the overall quality of the final product. Machining processes that produce burrs include compressing, piercing, cutting, bending, and shearing.

Deburring is crucial for many applications, as burrs can affect a part’s overall effectiveness, safety, longevity, and functionality. When left unaccounted for, burrs can cause the following issues:

- Material and fastener issues

- Increased stress in certain areas, resulting in decreased resistance to fractures

- Shortened fatigue life

- Improper seating of fasteners, which can lead to assembly or fastener damage

- Material failure caused by cracks

- Higher risk of corrosion

- Increased risk of static discharge due to concentrated electrical charge

- Undesired heat and friction

- Unsafe handling

- Lubrication issues caused by increased wear at interfaces

How Does Deburring Work?

Deburring can be accomplished in several ways, depending on component geometry, burr location and size, material, product volume, and cost. The following are some of the common deburring techniques:

- Mass Finishing. This procedure is useful when numerous parts or components need to be finished. It can be done in batch or continuous systems, and in dry or wet processes, depending on the product material.

- Brushing. Burrs are scraped off with brushes composed of thin wires or metal filaments attached to a revolving disc.

- Manual Deburring. This deburring method uses hand-held or mechanical instruments, such as brushes, grinders, sanders, and files, among others.

- Robotic Deburring. Robotic deburring involves a robotic arm with a grinding, deburring, or chamfering tool mounted on it.

- Sheet Metal Edging. Sheet metal edging equipment features pinch rollers or small grinding wheels that smooth the edges of sheet metal with thicknesses ranging between 0.025 to 0.25 inches.

- Mechanical Deburring. Mechanical deburring involves the use of machines to deburr the workpiece. Compared to manual deburring, mechanical deburring offers less control over localization and aggressiveness.

- Electrochemical Deburring. For applications requiring extreme precision and the removal of burrs from hard-to-reach areas, electrochemical deburring offers the ideal solution. It uses a combination of electricity and a glycol or salt solution to dissolve the burrs without affecting the rest of the material.

- Waterjet Deburring. Burrs and debris are eroded from the workpiece using the impact force of high-velocity water jets.

Benefits & Industries Served

Despite the difficulty and expense of the process, deburring is an important element of the manufacturing process for the following reasons:

- Burrs obstruct proper part fit and assembly

- Burrs operate as failure initiation locations, making parts vulnerable to fatigue and cracking

- On cracks and burr surfaces, corrosion is easy to form

- Burrs are a hazard to both workers and end users

- Burrs degrade the part’s visual quality

Industries such as metalworking, plastics, woodworking, and composites use deburring to improve efficiency and consistency in their finished products.

Why Apex Machine Group?

Deburring machines from Apex Machine Group have a unique design that enables both small and large pieces to run through the same machine. Our equipment features a specialized conveyor belt that firmly holds small parts, a scuffing mechanism that cleans the conveyor belt, and two 4″ dust ports for clearing debris from the belt, making it the ideal solution for shops that need to run components as small as 3″ x 3″.

Our machine features differ per model, including multiple headframes, heavy-duty structures, dual in-feed, and out-feed pinch rolls, motorized abrasive belts, air-loaded cylinders, and paper media filtering systems. Contact us today to learn more about our metal deburring machines and how they can help your shop’s bottom line.